Zustellung: Do, 05.06. - Di, 10.06.

Versand in 1-2 Wochen

VersandkostenfreiBestellen & in Filiale abholen:

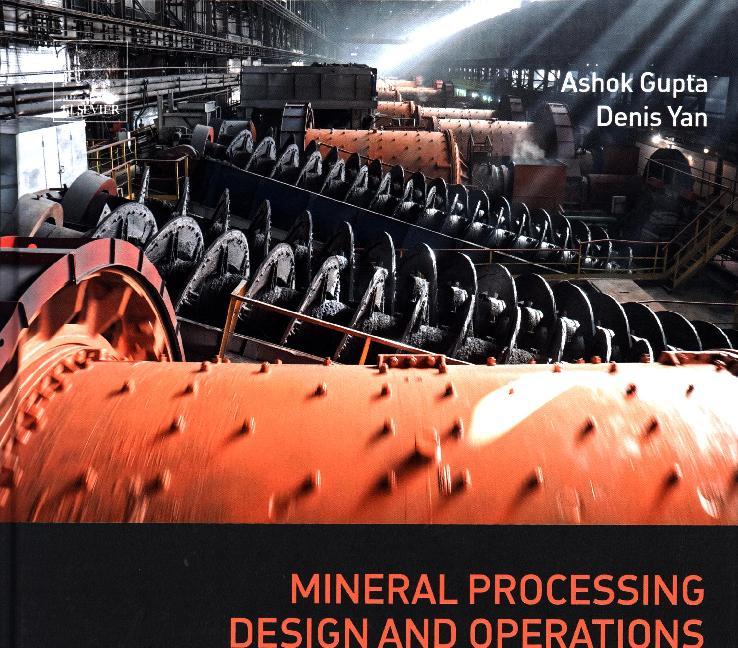

Mineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes. Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process. Covers the theory and formulae for unit capacities and power requirements to help the designer develop the necessary equipment and flow-sheets to economically attain maximum yield and grade.

This second edition describes theories and practices of design and operation of apparatus and equipment, including an additional chapter on magnetic, electrostatic, and conductivity modes of mineral separation. Basics of process controls for efficient and economic modes of separation are introduced.

Inhaltsverzeichnis

1. Mineral Sampling2. Particle Size Estimation and Distributions3. Size Reduction and Energy Requirement4. Jaw Crusher5. Gyratory and Cone Crusher6. Roll Crushers7. Tubular Ball Mills8. Tubular Rod Mills9. Autogenous and Semi-Autogenous Mills10. Stirred Mills - Ultrafine Grinding 11. Mathematical Modelling of Comminution Processes12. Screening13. Classification14. Solid - Liquid Separation - Thickening15. Solid Liquid Separation - Filtration16. Gravity Separation17. Magnetic and Electrostatic Separation18. Flotation19. Metallurgical Process Assessment20. Process Control

Produktdetails

Erscheinungsdatum

28. Juli 2016

Sprache

englisch

Autor/Autorin

Ashok Gupta, Denis S. Yan

Verlag/Hersteller

Produktart

gebunden

Gewicht

1960 g

Größe (L/B/H)

43/186/232 mm

ISBN

9780444635891

Entdecken Sie mehr

Bewertungen

0 Bewertungen

Es wurden noch keine Bewertungen abgegeben. Schreiben Sie die erste Bewertung zu "Mineral Processing Design and Operations" und helfen Sie damit anderen bei der Kaufentscheidung.